SHAPES DEVELOPMENT ON CUSTOMER’S NEED

The growing demand of special profiles has oriented the company to optimize the production into two separate divisions: standard and specific. The design and the production of special prodiles is followed by a technical office that deals directly with the customer and lead to a product that corresponds perfectly to the customers’s need in terms of quality and requested tolerances. The production circle is digitalized, the customized packaging and the traceability of the material with special labels give us the chance to a greater flexibility and quicker deliveries.

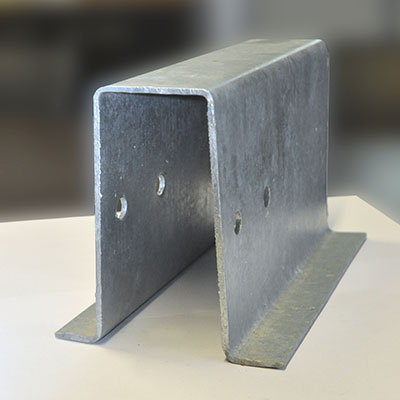

PROFILES IN FIXED LENGHT

Fixed lenght cut profiles with holes based on customer’s demand.

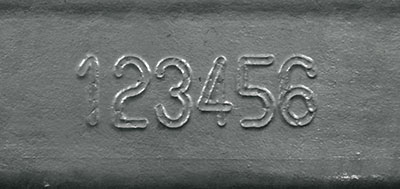

MARKING THE PROFILES

The marking of each single piece allows the traceability of the profiles even after the hot dio galvanization process.

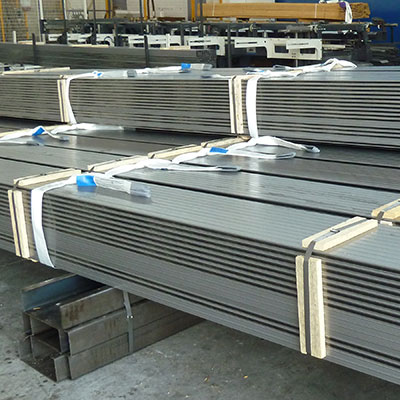

SPECIAL PACKAGING

The packaging of the product is realized specifically according to the customer’s request

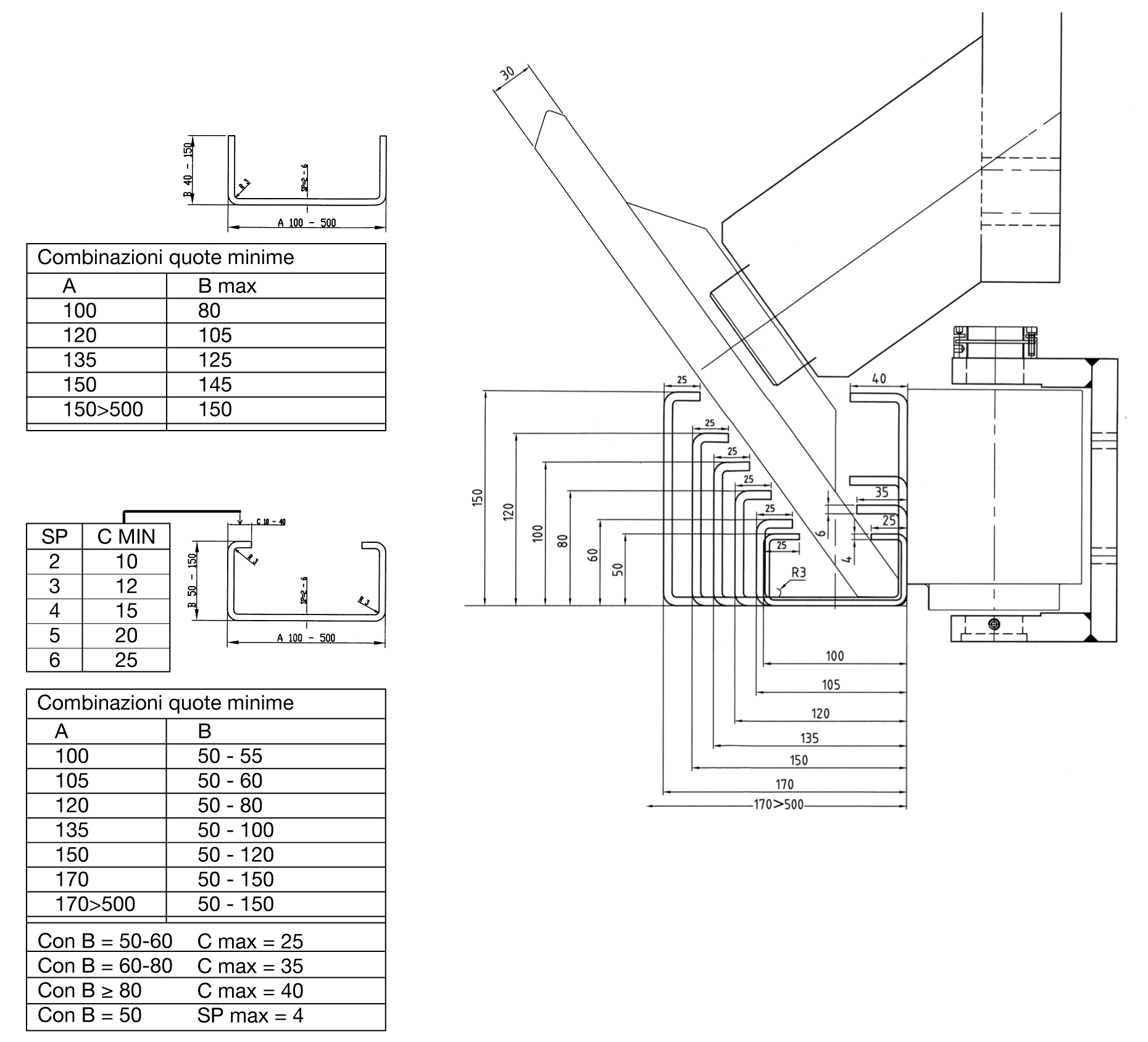

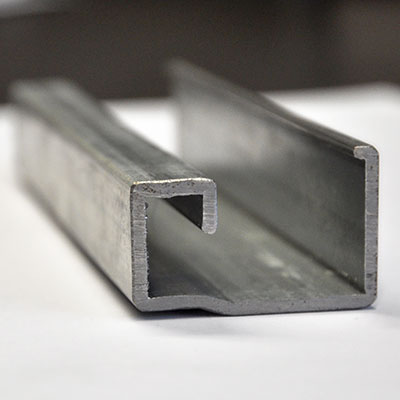

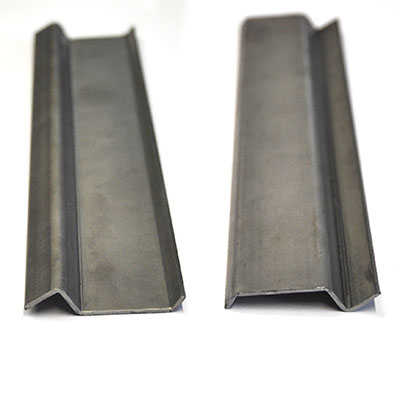

LAST GENERATION PROFILING TECHNOLOGIES

The use of a new profiling system allows the production of U- and C-profiles with bases from 100 to 500 mm, with an automatic calibration of the thickness from 2 to 6 mm.

The production of the material in this way leads to a higher quality system.

PUNCHING ACCORDING TO THE DRAWINGS

The drilling line and cutting to size also allow bringing out a product ready for final uses, with marking of every single piece in order to allow the tracing even after hot dip galvanizing.